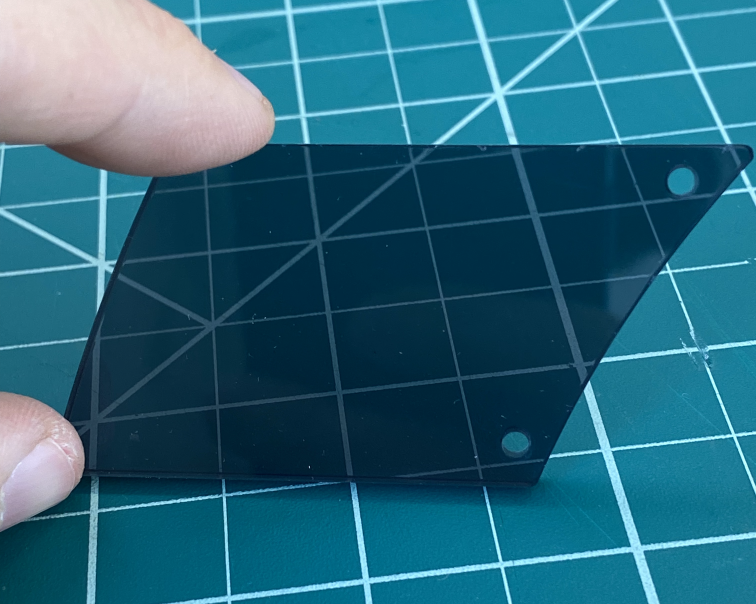

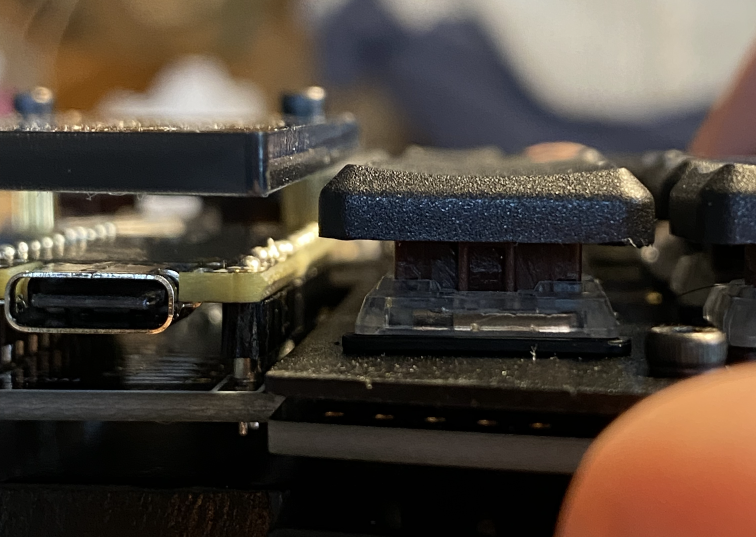

Although most of the first-party Kyria case is opaque matte black, the little cover for the microcontroller is a piece of transparent gray acrylic.

It’s see-through so that you can put an OLED screen on top of your microcontroller, for some reason, although since this is a battery-powered keyboard that makes even less sense than usual.

I tried installing it anyway – to show off my solder joints? – but I really hated it.

I thought it looked fine. But it’s set so high up that, with the low-profile Choc keys, my finger would brush against it when I typed the inner keys. Any time I reached for the T key I would feel the sharp corner of the acrylic, which was really unpleasant.

So I ordered some shorter standoffs for it, so that it wouldn’t stick up above the keys.

But I was still concerned about the sharp edge, even if I wasn’t coming directly up against it. And I didn’t think I could radius the translucent acrylic without destroying the finish and making it look terrible, so I decided to make some new covers.

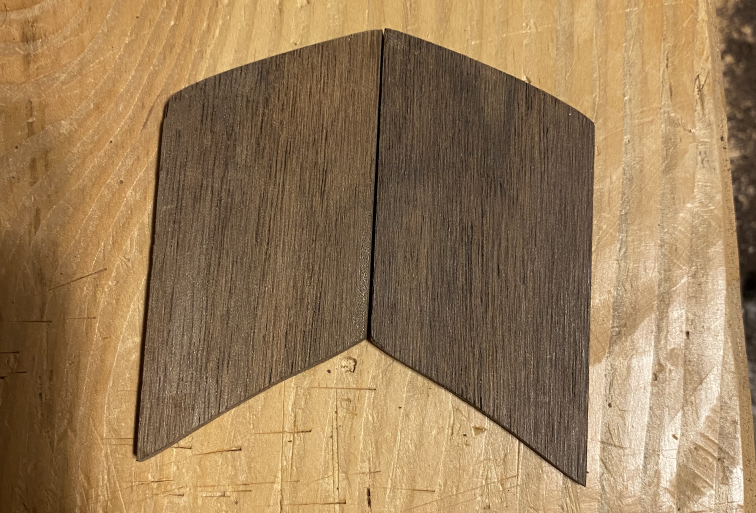

I had a scrap of 1/4" walnut lying around, so I traced the outline of the acrylic shield and cut it out with a hand saw and a file.

Then I sawed the piece in half, giving me two identical shields.

If this wood had had any interesting grain I would have finished this side – planed off those saw marks – and I’d have a bookmatched pair. But since this was a very boring piece of scrap wood, I didn’t bother, and instead just used the “outside” edges. Which were already pretty smooth.

That was all the shaping I did. I sanded the corners smooth, and then went on to finish it.

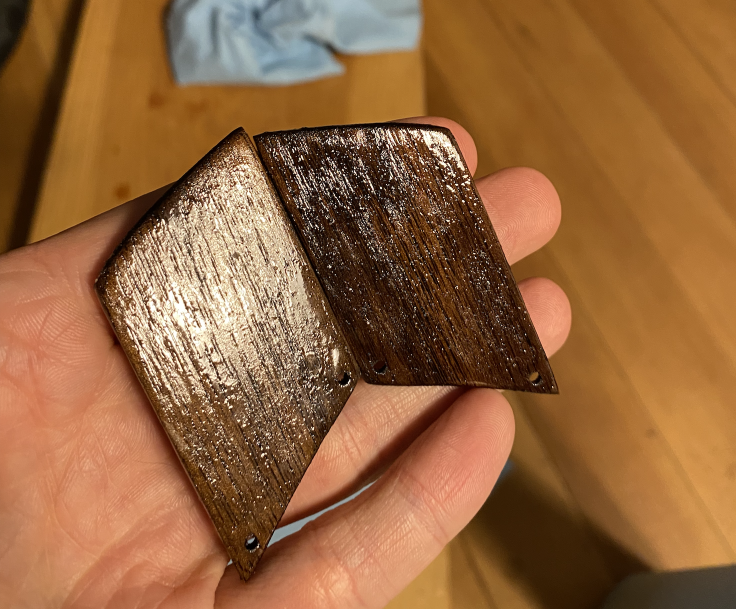

I had a leftover can of shellac from some project I did a long time ago, and I thought that would look nice on the keyboard. Shellac is very easy to apply, and I thought that a slightly glossy finish would make a nice contrast to the matte keys.

But it did not.

Because shellac, apparently, goes bad.

Shellac normally dries in a few seconds: it’s a resin dissolved in alcohol, and as the alcohol evaporates, it leaves the solid resin deposited on the surface. But my shellac… wasn’t drying. It was just… gummy. Gummy and horrible. Even though the alcohol was evaporating in a few seconds, it was leaving behind something that was decidedly not shellac.

It turns out that, once shellac dissolved in alcohol is exposed to air, it starts to spoil. The can I was using had been open for over a year, and in that time it transformed itself into something disgusting and gooey. That I then smeared all over my freshly shaped walnut covers.

Ugh. It’s normal to have to sand shellac smooth, but I couldn’t do that here, because it wasn’t actually solid – it would just sort of smear around and gum up my sandpaper.

Fortunately, it was still easy to remove: I dissolved it with some denatured alcohol, and scrubbed it off with a shop cloth. It took a little while, and I wish that I had realized something was wrong with my shellac a bit sooner, but in the end I didn’t have to start over. So no real harm done.

In lieu of shellac, I just rubbed some furniture wax on them. It doesn’t do much to accentuate the grain, but there’s not much grain here to accentuate anyway, so whatever.

I still plan on making new covers one day: I don’t like the visible screws, and I’d like a prettier piece of wood with grain that I can bookmatch. I’ll revisit the shellac finish if I ever get around to that.

But it’s good enough for now.

And now, with the final piece of the keyboard complete, all that’s left to do is flash this thing.