While waiting for my keyboard kit to arrive, I stumbled upon a video of someone actually typing on a Kyria with the tenting puck, and I was not thrilled with what I saw.

Something is bending there, but it’s hard to tell what: is it the keyboard itself? Or the strange spring-loaded tripod mount thing that it’s mounted on?

I decided, without any evidence, that it was probably a combination of both. I had my own ideas about tripod mounting, so I didn’t have to worry about the springiness of that particular setup, but I was concerned about the keyboard itself bending when in use.

And I thought there was a pretty easy fix.

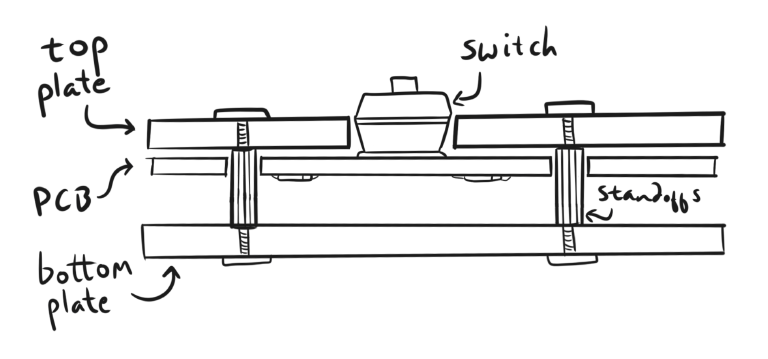

So the Kyria keyboard is made up of three layers: a bottom plate, a PCB, and a top plate.

In the case that splitkb.com sells, the top and bottom plates are both made out of 3mm thick pieces of acrylic – which is a little thinner than 1/8". Thin acrylic like this is pretty flexible, and while the PCB material is stiffer, it’s also thinner, so this setup didn’t sound like it would be very rigid.

But I made that assessment completely without evidence, as I had not yet received any of the parts, and was basing this all on a few seconds of random YouTube footage. But I decided to start solving a problem that might not even exist anyway, because it sounded like a fun thing to experiment with.

The fix seemed easy: get a stiffer plate. 3mm acrylic is bendy. 3mm aluminum is not. So… how do I get a 3mm aluminum plate?

The creator of the Kyria publishes DXF files for the case, which can be fed into any laser cutter or CNC machine. I don’t have a laser cutter or a CNC machine, but I had learned from my custom mechanical keyboard research that there are companies that will do on-demand manufacturing of parts like this.

One name in particular kept coming up, SendCutSend, so I uploaded the “Kyria Plate Case Bottom - 6 columns - Puck - No Kerf.dxf” file, just to see what it would cost to have it cut out of 3mm aluminum.

The answer?

$6.38 each.

I was kind of blown away by this. A custom cut piece of aluminum, for $6.38? Where I live that’s, like, the price of a latte. I immediately hit the buy button.

SendCutSend had a $19 minimum for 3mm aluminum, so I ended up ordering four of them, for a grand total of $25.52.1

I thought that the extras would come in handy for experimenting with finishes: plain aluminum is pretty ugly, and I planned to try to finish it… somehow. Brushing? Sand-blasting? Painting? I thought it would be good to have some backups to experiment on.

I was not entirely sure if this would work. I didn’t know if the parts would actually align with the splitkb parts, if SendCutSend would get the kerf calculations correct, if the tiny screw holes would be the correct size, if anything would turn out to be anything. But I was willing to pay $25 to find out.

I ordered the parts on October 31 and received them on November 8: eight days later.

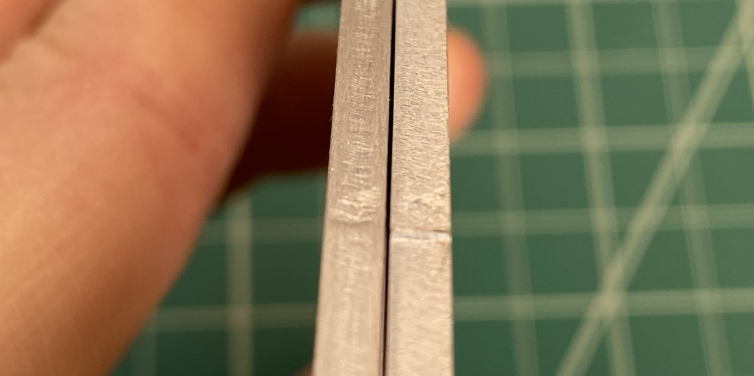

They looked really good. Each piece was exactly identical; they had been deburred perfectly. There were no sharp edges. They each had a small bump where the laser finished cutting them out – I’m assuming – that I would have to file down by hand, but that was no big deal.

But I had no idea if they would actually fit with the splitkb.com parts, because those parts hadn’t even shipped yet. My splitkb.com order wouldn’t ship for another fifteen days, as a matter of fact. So I had to wait before I could pass real judgment on the plates.

In the meantime, I needed to find some switches.

-

The minimum seems to have gone up to $29 after I placed this order. ↩︎