There are lots of different types of keyboards, and no standard way to talk about them. You might hear people throwing around terms like “40% keyboard” or “62-key keyboard” or “tenkeyless.”

These terms are completely meaningless to me, but to people deeply embedded in the world of custom keyboards I guess they mean something.

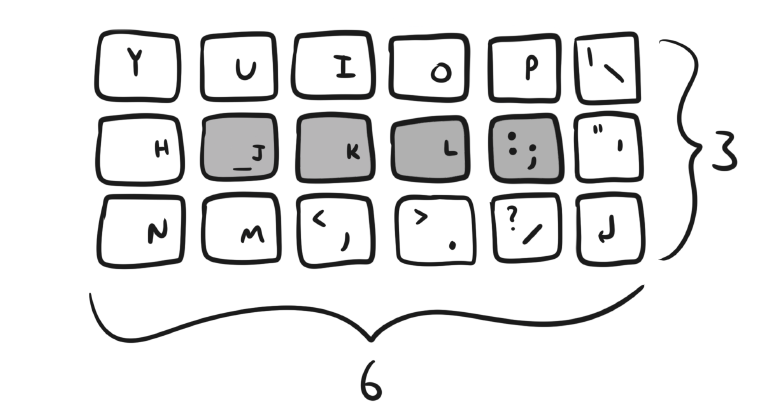

But there is a classification that’s meaningful to me, that makes sense, and is fairly unambiguous: row/column notation. For example, the keyboard I built is a “3x6” keyboard. This means that, for each hand, there are 3 rows and 6 columns of keys:

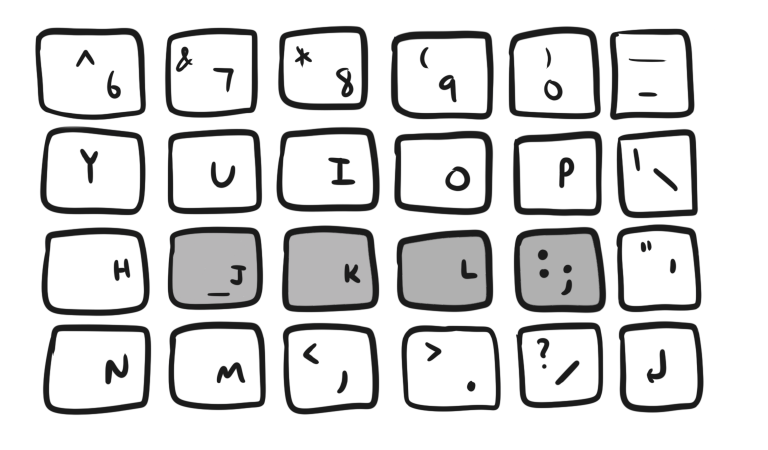

“4x6” keyboards are also popular:

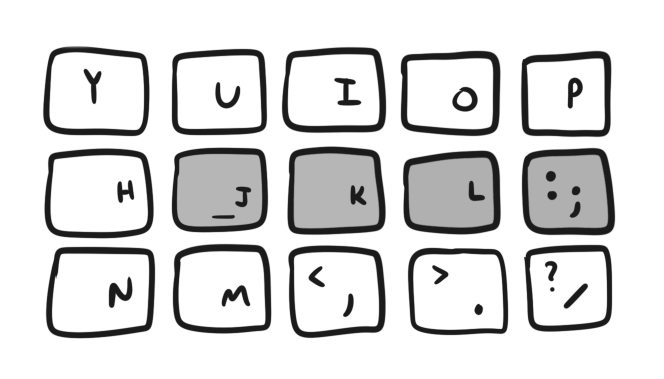

And “3x5” keyboards:

Note that this notation tells you nothing about the arrangement of the thumb keys, but it’s a useful abbreviation for how compact the main body of the keyboard is.

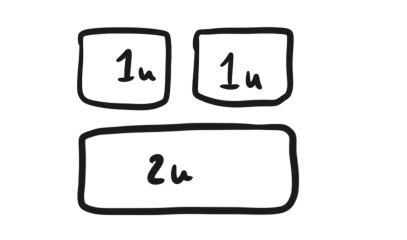

Another weird keyboard term is “1u,” “1.5u,” “2u,” etc. This refers to the size of an individual key. A “normal” key is a 1u, but many keyboards have larger keys for modifiers or the enter key or whatever.

The “u” seems to stand for “unit,” which is… annoying, but here we are.

How keyboards work

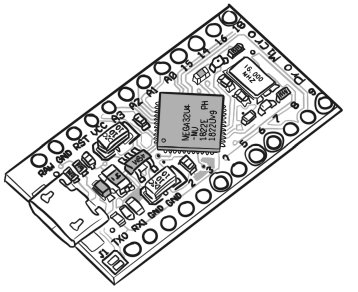

Something that I didn’t know going into all of this was that many keyboards outsource all of the complexity of being a keyboard into a small device called a Pro Micro:

The Pro Micro contains all of the wizard’s crystals required to speak USB to a computer, and you can make a keyboard by connecting switches to some of the holes running along the side of the PCB. Or, if you have more switches than holes, you can add a diode to every switch and then wire them in sort of a grid pattern, so that each row and each column gets a hole on the Pro Micro. (The grid wiring is how most keyboards work in practice.)

In fact, some keyboards don’t even have PCBs. They just have “plates” – a rigid frame that holds the switches in the right positions – and then wires and diodes soldered directly to the switches and to a Pro Micro. These are called “hand-wired” keyboards, and if you look at a guide to hand-wiring a keyboard you can get a pretty good idea of how electronically simple keyboards actually are, when you have a Pro Micro to do the heavy lifting.

But even if you have a PCB of your very own, there’s an advantage to outsourcing the brains to a separate microcontroller board: these boards are modular. And over the years, various “Pro Micro compatible” devices have cropped up, and any keyboard designed to take a Pro Micro can actually take any one of the alternatives.

The Elite-C, for example, lets you use USB-C instead of Micro USB. And the nice!nano gives you USB-C and Bluetooth.

Let me repeat that: any keyboard designed to take a Pro Micro – which is a pretty large subset of “custom” ergonomic keyboards – can, just by swapping out a different rectangle, become a Bluetooth keyboard.

This is very neat.

I didn’t know this when I started my journey, and had no idea that Bluetooth ergonomic keyboards even existed. They definitely didn’t a few years ago, and as far as I can tell they’re still only available in DIY projects like this.

But there are a few commercial offerings scheduled to appear in 2022, so some time in the next year you might be able to buy one off the shelf. But right now, if you want a wireless ergonomic split keyboard, you’ll have to come with me.